First of all, I have to apologize for our inconsistent delivery over the last few months.

Why can't we just plan better and always have enough cocoa in stock?

Believe me, I've asked myself this question often enough over the past few months.

As hard as we try to estimate demand, we're just as often wrong. The challenges are:

1. We are a rapidly growing company - and growth is rarely linear.

If we sold 300kg this month, we need 450kg or 600kg next month. We can try to manage that with our marketing efforts, but (fortunately) many of you tell your friends about our cocoa and that's how we get traffic even without marketing..

2. Our manufacturer, who produces fantastic quality, can't keep up fast enough with these volumes.

Although new machines have already been ordered, they will not arrive until the summer.

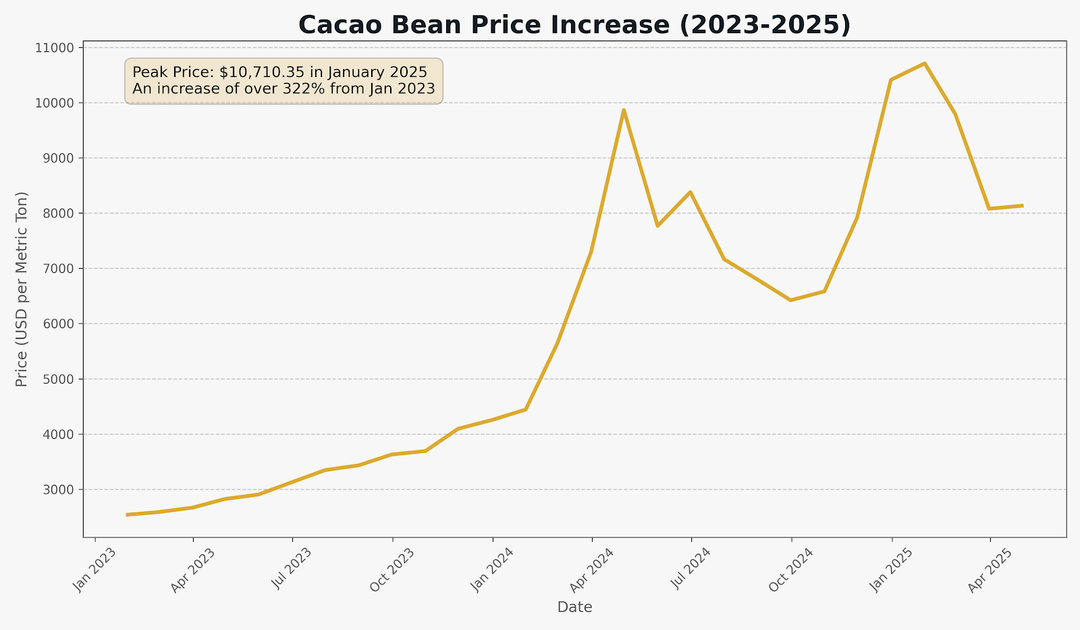

The cocoa bars that we sell are not off-the-shelf goods but are specially produced for us according to our requirements. We are currently in a tricky situation because the small "Bean to Bar Craft Chocolate" Manufacturers can no longer produce in our quantities - the large manufacturers, on the other hand, require quantities of at least 1 ton per type and produce in a quality that has not yet proven itself for us (they use completely different machines and processes).

Why don't we just order "way too much" and always have a buffer in stock?

1. In my experience, cocoa should not be stored for too long, but should be enjoyed as fresh as possible after roasting and grinding. Filling up our warehouse is therefore not an elegant solution.

2. Cash. We sell quality cocoa with a relatively low margin. We would have to tie up a lot of cash to fill up the warehouse. No young company can afford that. So far we've grown 100% without investors and are well on our way to not having to change that.

And now?

Of course it can't go on like this, we all know that. That's why I'm currently in talks with additional manufacturers who can supply us with other varieties in the usual quality.

In addition, we will optimize some processes with the existing manufacturer in order to be able to produce subsequent deliveries more quickly. For example, we're starting to stock the most popular varieties of raw cacao beans (Porcelana Mexico , Sur del Lago Venezuela , and Indio Rojo Guatemala ) in his factory instead of ordering them on-demand. This saves us e.g. 2 weeks transport time from the port in Amsterdam to the chocolate factory.o-Fabrik.

In addition, we are learning a lot more on the marketing side and are now able to control the stream of new customers better and better so as not to overwhelm our capacities.

Another change is the cooperation with a professional shipping company (fulfillment center) from April 19, which will send the cocoa from their warehouse to you in 90% of all cases the very next day. With more than 400 orders / month, we couldn't keep up with packing ourselves and hope that the cooperation will above all give you a faster and more consistent shipping experience.

The past few months have been wild - but also instructive. Above all, we now have a new benchmark for shipping volumes that we can use to calculate.

Thank you very much for your patience and I am happy when you all finally receive your cocoa.

best regards,

Jonas

Founder Moruga Cacao

I drank while writing:Sur de Lago from Venezuela🇻🇪

Leave a comment